A World of Difference.

Made Possible.

Our next generation packaging solutions create memorable moments now and make lasting impact on people, products, and world-class brands.

SOLUTIONS

Our Approach to Packaging

It’s the difference-maker for your business – if you do it right.

Consumer Experience

More consumer ease and enjoyment. Less environmental impact.

Environmental Impact

Making a positive difference for people and planet starts with the materials you choose.

Brand Elevation

First impressions matter. Let’s make sure you stand out on the shelf.

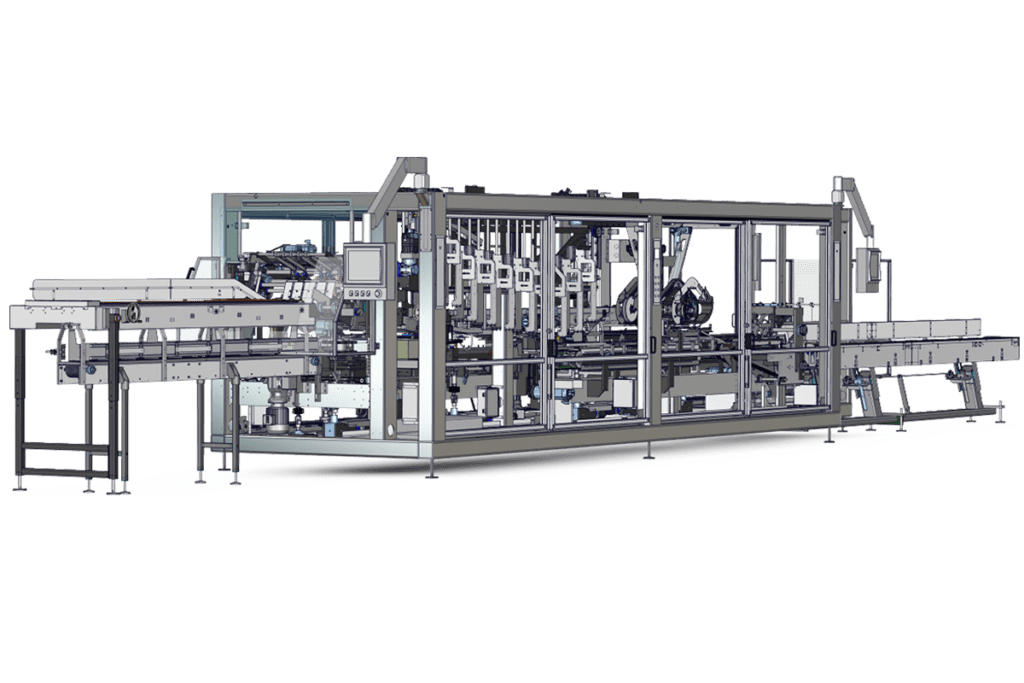

Operational Efficiency

Get to scale without giving up customization or quality.

INNOVATION

Next-Generation Packaging is Here

We take seriously our responsibility to deliver packaging solutions that meet the demands of our clients, markets, people, and planet.

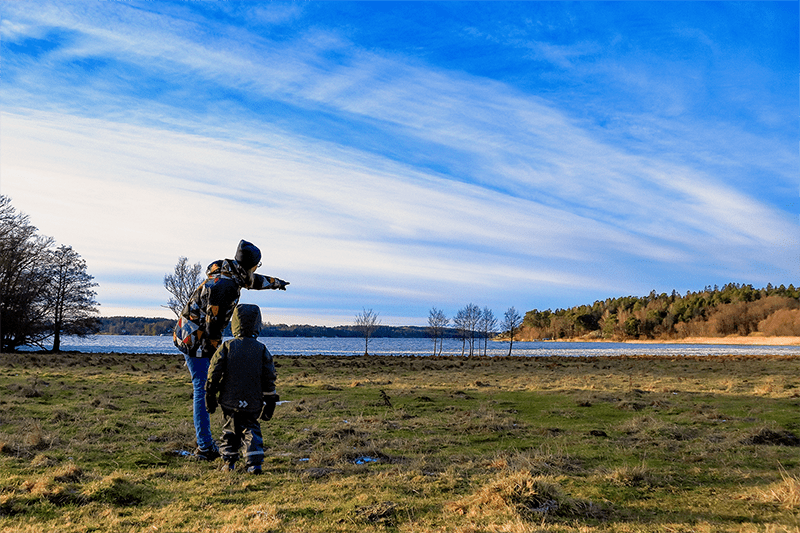

SUSTAINABILITY

Better, Every Day

Paperboard packaging is a tangible way we help leave the world a better place for future generations. But there’s a lot more to it than that.

Graphic Packaging: Most Innovative Company 2023

Fast Company has recognized Graphic Packaging on its list of the World’s Most Innovative Companies for 2023.

news & events

What’s Happening at Graphic Packaging

See where we are making an appearance at industry events and get the latest news.